- protects and manages batteries from 12 to 48 Volt

- simply connect 5 wires per four cells stack and the EMS is operational

- measures each cell’s voltage and temperature

- 4 Amp active differential cell balancing based on open cell voltage

- 20 custom monitoring ranges (voltage, temperature, SOC) to trigger alarms and/or relay outputs

- 6 NO/NC isolated relay outputs for remote control of external equipment or switching devices

- charge management to start and stop chargers on your terms

- integrated pre-charge commands for capacitive loads

- manages the connection of a backup battery when needed

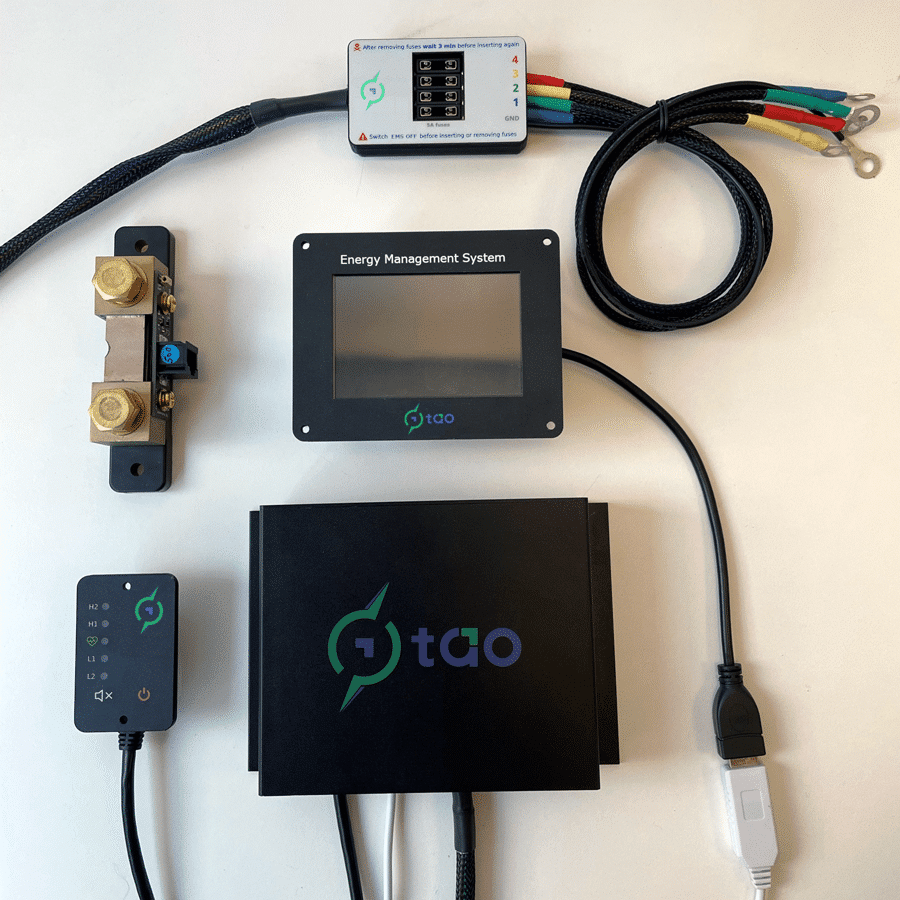

- high-precision current measurement for accurate SOC estimation

- measures cell resistance and actual battery capacity to estimate state of health

- remote LED and control panel with relay reset and emergency shutdown button

- continuous self-diagnostics

- PC and Mac application for configuring the BMS and monitoring the battery

- fault simulation mode to validate the configuration and indicate that all connected equipment is functioning correctly